1 Accuracy

Scraping

for accuracy

“Aiming for 1 μm”

In order to challenge areas that are impossible with only machining and to make machines with perfect linear axes, YASDA continues to utilize the scraping process.

Temperature control

for accuracy.

In order to assemble the high accurate parts finished by scraping, it is important to suppress temperature changes in the factory during assembly.

At YASDA, the temperature in the factory is thoroughly controlled, and the temperature change in 24 hours is kept within 0.5℃. The temperature difference between the floor surface and 5 meters from the floor is kept within 0.6℃.

Factory temperature control

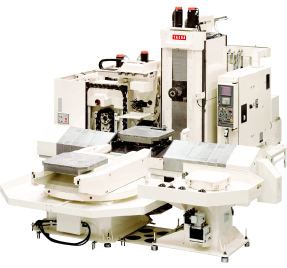

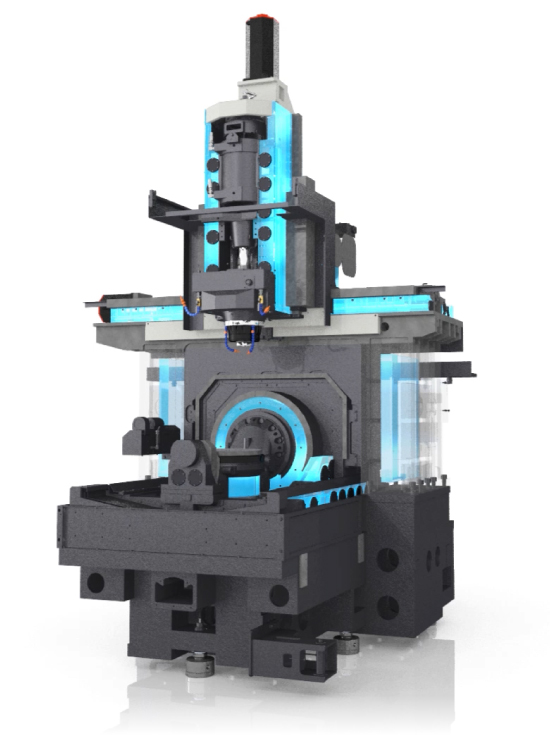

2 Rigidity

Guideway

for rigidity

The highly rigid box guideway is fixed to the mounting surface, which is straightened by scraping. This improves vibration damping and achieves both high rigidity and high precision.

Construction

for rigidity

The total weight of the machine supporting a 100kg workpiece is 8,000kg.

The logic of machine weight ≈machine rigidity is a principle that has not changed even with the advancement of technology.

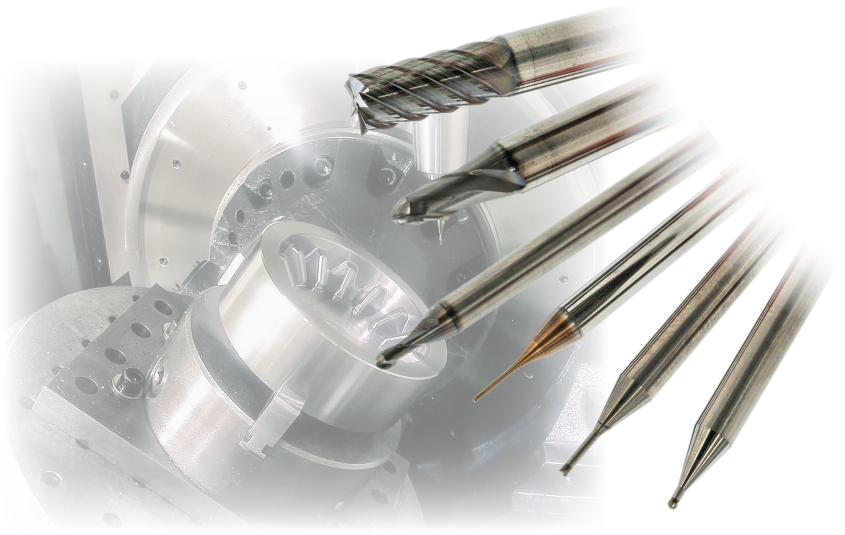

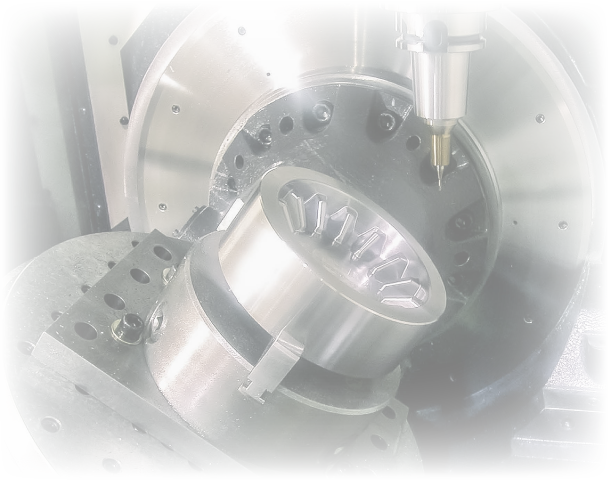

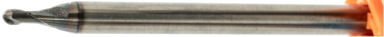

Long tool life supported

by rigidity

By combining a highly rigid machine with a high-precision spindle, tool wear caused by vibration during machining, spindle runout, etc is minimized.

3 Stability

Thermal displacement control

for stability.

YASDA’s thermal distortion stabilizing system prevents sudden geometry change of the machine due to temperature change in the surrounding area by circulating the heat exchange liquid controlled at ±0.2°C relative to the room temperature throughout the machine.

This enables stable, high-precision machining for a long time.

4 Long life

YASDA‘s machines, which assemble straight parts together without stress, are resistant to geometry changes even after years of use, and achieve high-precision machining for a long time.

It is possible to continuously satisfy the ever-increasing precision requirements for products.

Machine accuracy changes

Example of “YBM 60N”

Duration of use:

28 years 11 months

116,000 hours: 11h/day

X axis ± 0.001

Y axis ± 0.001

Z axis ± 0.001

years

X axis ± 0.002

Y axis ± 0.002

Z axis ± 0.001

X axis 0.001

Y axis 0.001

Z axis 0.001

years

X axis 0.001

Y axis 0.001

Z axis 0.003

0.003

years

0.008

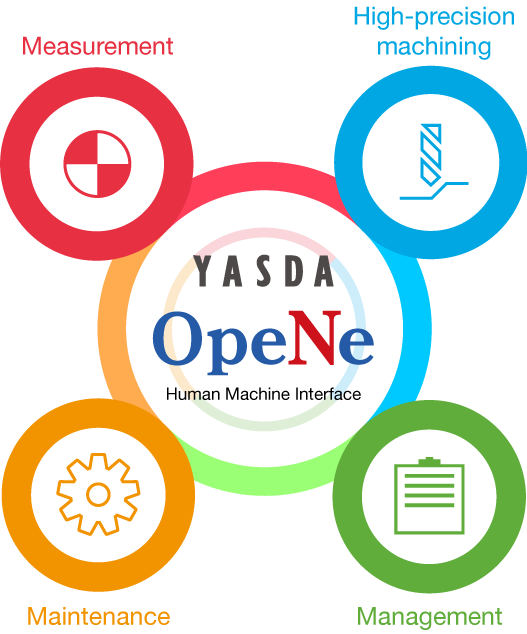

5 Easy to use.

High precision to everyone.

More easy and more user friendly by YASDA’s original software

Measurement

YASDA machines are equipped with a

variety of measuring instruments

aiming to Maintain accuracy of workpiece

and to reduce work of operator

High Precision Machining

Advanced measurement functions provide

complete support for high precision

machining

Maintenance

Preventive maintenance by monitoring

machine condition

Management

It is possible to visualize running time,

machining time, spindle rotation time,

and temperature around the machine.

addition, tool information and machining

schedules can be managed.